Polytetrafluoroethylene (PTFE) fabric is an innovative material that has revolutionized various industries with its unique properties.

This article will explore the depths of PTFE fabric, its origins, characteristics, applications, and prospects.

By the end of this article, you will have a comprehensive understanding of this exceptional material and its crucial role in today’s world.

When Did PTFE Fabric Appear?

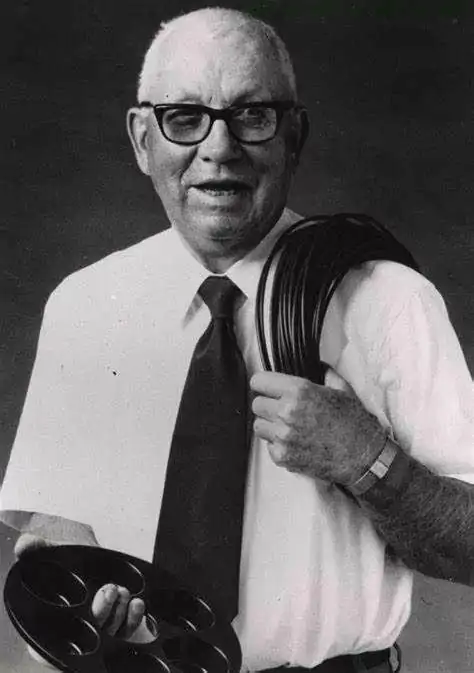

PTFE, commonly known as Teflon, is a synthetic fluoropolymer of tetrafluoroethylene, first discovered in 1938 by chemist Dr. Roy J. Plunkett.

The fabrication of PTFE into fabric involves weaving or knitting PTFE-coated fibers or yarns, which are then treated with a specialized heat-setting process.

This treatment locks in the PTFE coating and enhances the fabric’s strength and stability.

What are the Unique Characteristics of PTFE Fabric?

PTFE fabric possesses a remarkable set of properties that make it an ideal choice for various applications:

Non-stick surface: PTFE fabric is best known for its non-stick property due to its extremely low coefficient of friction. This attribute makes it suitable for applications where the release of adhesives, chemicals, or food is necessary.

Chemical resistance: PTFE fabric is virtually inert to most chemicals and solvents, making it perfect for use in harsh environments where exposure to corrosive substances is dai.

Temperature resistance: With an operating temperature range of -328°F to 500°F (-200°C to 260°C), PTFE fabric can withstand extreme temperatures while retaining its physical properties.

High tensile strength: PTFE fabric exhibits remarkable strength and durability, making it resistant to wear and tear.

UV resistance: The fabric is resistant to ultraviolet radiation, maintaining its integrity and appearance even under prolonged exposure to sunlight.

Hydrophobic and oleophobic properties: PTFE fabric repels water and oil, making it suitable for high cleanliness and low maintenance applications.

Where Will PTFE Fabric Be Used?

The exceptional characteristics of PTFE fabric have led to its widespread use across various industries:

- Food processing: PTFE fabric is utilized in conveyor belts, baking sheets, and release liners to facilitate the easy release of food products without compromising their quality.

- Electronics: Due to its excellent dielectric properties, PTFE fabric is used as an insulator in printed circuit boards and other electronic components.

- Textile industry: PTFE fabric finds use in the manufacturing of protective clothing, such as chemical suits, firefighting gear, and outdoor apparel.

- Architecture: PTFE-coated fiberglass fabric is often employed in constructing tensile structures, offering lightweight, flexible, and durable solutions for various architectural designs.

- Aerospace and automotive: PTFE fabric is used in gaskets, seals, and other components that require resistance to extreme temperatures and chemicals.

Future Prospects of PTFE Fabric

As technology advances and new applications emerge, the demand for PTFE fabric is expected to grow. With ongoing research into developing more sustainable and eco-friendly manufacturing processes, PTFE fabric is poised to become an even more integral part of the material landscape.

PTFE fabric is a versatile, high-performance material with distinctive characteristics, making it indispensable in various industries. Its impressive properties and a growing list of applications ensure that PTFE fabric will continue to be a key player in the future of material science and engineering.

LinkCoo provides a variety of specifications of PTFE fabrics to meet the product requirements of different industries. Contact LinkCoo’s team to obtain the most professional PTFE product solutions.