Home » Thick PTFE Film Tape

Thick PTFE Film Tape

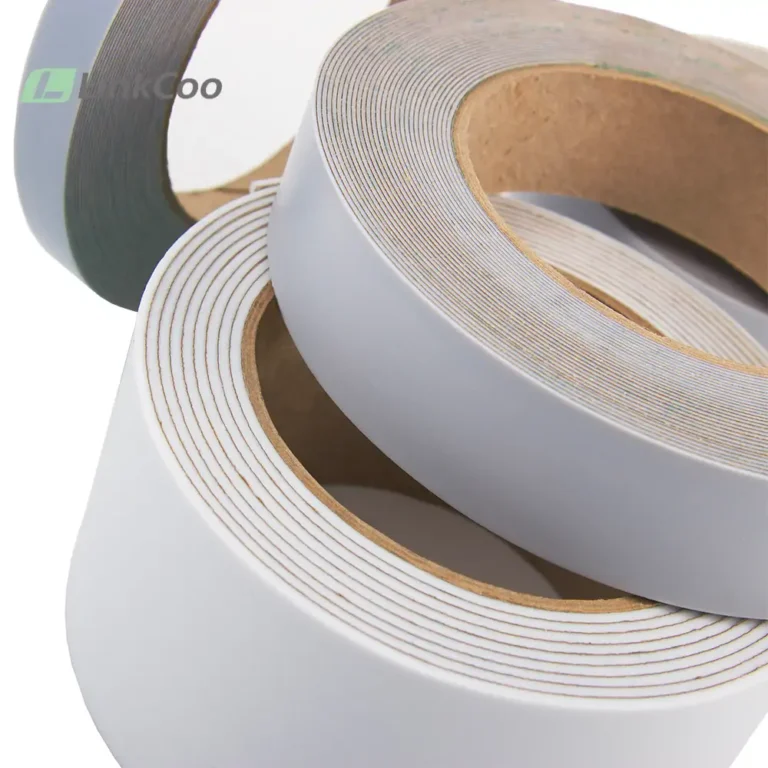

Thick PTFE Film Tape is a high-strength, PTFE tape designed to meet the rigorous demands of industrial applications. Its increased thickness, ranging from 0.13 mm to 0.8 mm (0.005″ to 0.031″), ensures exceptional tensile strength, dimensional stability, and durability under high-pressure and high-temperature conditions. This enhanced structural integrity makes it ideal for applications requiring long-lasting performance in challenging environments.

Capable of withstanding extreme temperatures from -73°C to 260°C (-100°F to 500°F), Thick Film Tape is engineered for industries such as aerospace, chemical processing, automotive, and food packaging. Its optional high-temperature silicone adhesive backing ensures secure placement, even on complex or irregular surfaces.

Certified under RoHS, UL94 V-0, and ASTM D3308, Thick Film Tape provides compliance with global safety and quality standards, making it a trusted choice for critical industrial applications.

Thick Film Tape sets itself apart with its advanced thickness and reinforced PTFE-coated fiberglass construction. Unlike standard PTFE tapes, the thicker profile significantly enhances its mechanical strength, making it resistant to creep, elongation, and deformation under high-pressure or thermal stress. Its low-friction PTFE surface minimizes wear, ensuring consistent performance and reduced maintenance in dynamic applications such as conveyor belts and sliding components.

Additionally, the tape’s chemical inertness ensures it remains unaffected by aggressive chemicals, including acids, alkalis, and solvents, making it ideal for use in chemically harsh environments. Combined with its high-temperature performance and non-stick properties, Thick Film Tape excels in applications where durability, thermal resistance, and low maintenance are critical.

Why Thickness Matters:

The increased thickness (up to 0.8 mm) provides greater durability and load-bearing capacity, which is particularly beneficial in high-pressure gaskets, sealing systems, and heat insulation layers. This added strength ensures a longer lifespan compared to thinner PTFE tapes, reducing the need for frequent replacements and lowering operational costs.

Thick Film Tape is the ultimate solution for high-performance industrial applications requiring superior durability, chemical resistance, and thermal stability. Its enhanced thickness and compliance with global certifications make it a trusted choice for industries demanding reliable, long-lasting solutions. Contact LinkCoo today to learn how Thick Film Tape can optimize your operations and improve your system’s performance.

Enhanced Thickness for Heavy-Duty Applications: Available in thicknesses up to 0.8 mm, providing exceptional strength and dimensional stability under heavy loads.

Wide Operating Temperature Range: Performs reliably from -73°C to 260°C (-100°F to 500°F), making it suitable for extreme thermal environments.

Chemical Resistance: Inert to acids, alkalis, solvents, and other aggressive chemicals, ensuring long-term performance in harsh environments.

Non-Stick Surface: PTFE coating offers low-friction, anti-adhesive properties, minimizing material buildup and improving operational efficiency.

Optional Silicone Adhesive Backing: High-temperature adhesive ensures secure application on metal, glass, or composite surfaces, even in challenging conditions.

Certified Safety and Quality: Complies with RoHS, UL94 V-0, and ASTM D3308, guaranteeing reliable performance and adherence to global standards.

| Attribute | Value (Metric) | Value (Imperial) |

| Material Composition | PTFE-coated fiberglass fabric | PTFE-coated fiberglass fabric |

| Adhesive Type | High-temperature silicone (optional) | High-temperature silicone (optional) |

| Thickness Range | 0.13 mm to 0.8 mm | 0.005” to 0.031” |

| Width Range | Up to 1,000 mm | Up to 39.37 inches |

| Operating Temperature | -73°C to 260°C | -100°F to 500°F |

| Tensile Strength | ≥ 200 N/cm | ≥ 114.28 lbf/inch |

| Elongation | ≤ 100% | ≤ 100% |

| Chemical Resistance | Resistant to acids, alkalis, solvents | Resistant to acids, alkalis, solvents |

| Certifications | RoHS, UL94 V-0, ASTM D3308 | RoHS, UL94 V-0, ASTM D3308 |

1. High-Pressure Gasketing

- Industry: Aerospace, automotive, and chemical processing.

- Function: Serves as a durable and creep-resistant gasket material for high-pressure sealing applications.

- Advantage: Reduces material deformation under load, ensuring consistent and long-lasting sealing performance.

2. Industrial Insulation

- Industry: Electronics, telecommunications, and industrial manufacturing.

- Function: Acts as a reliable insulating layer for electrical components and high-temperature equipment.

- Advantage: Prevents heat loss and protects components from thermal stress, ensuring efficient energy use.

3. Heat Sealing Applications

- Industry: Food packaging, pharmaceuticals, and textiles.

- Function: Provides a non-stick surface for sealing bars in high-temperature heat-sealing machines.

- Advantage: Enhances seal quality, reduces residue buildup, and minimizes downtime for cleaning and maintenance.

4. Conveyor Belt Linings

- Industry: Food processing, industrial automation, and textiles.

- Function: Offers a friction-reducing liner for conveyor systems exposed to high thermal or mechanical loads.

- Advantage: Extends conveyor belt lifespan and reduces maintenance costs.

5. Sliding Components and Bearings

- Industry: Industrial machinery, robotics, and automotive.

- Function: Provides a low-friction, wear-resistant surface for sliding and rotating components.

- Advantage: Reduces wear and tear, improving precision and operational efficiency.

Client: Nestlé (Food Packaging)

- Challenge: Residue buildup on heat-sealing bars caused frequent downtime and reduced sealing quality.

- Solution: Replaced traditional sealing materials with Thick Film Tape for its non-stick properties and durability.

- Result: Reduced downtime by 40% and improved seal consistency, ensuring higher production efficiency.

Client: Airbus (Aerospace)

- Challenge: Gaskets in fuel systems experienced creep under high-pressure conditions, leading to frequent replacements.

- Solution: Introduced Thick Film Tape as a creep-resistant sealing material.

- Result: Increased gasket lifespan by 50%, reducing material failures and maintenance costs.

Client: Dow Chemical (Chemical Processing)

- Challenge: Harsh chemicals caused rapid degradation of traditional insulation layers.

- Solution: Applied Thick Film Tape for its chemical inertness and durability.

- Result: Extended insulation lifespan by 60% and reduced operational disruptions.