Home » PTFE Conveyor Belt

PTFE conveyor belts are designed to meet the rigorous demands of industrial applications, providing exceptional temperature resistance, chemical resistance, and non-stick properties. Known for their durability and versatility, PTFE belts are the preferred choice in industries such as food production, textile manufacturing, electronics, and packaging.

Engineered to perform in extreme environments with temperatures ranging from -70°C to 260°C (-94°F to 500°F), PTFE belting offers unmatched reliability in processes like curing, heat sealing, and material handling. Backed by global certifications such as FDA, RoHS, and REACH, these conveyor belts ensure safety and compliance across critical industries. Whether you need PTFE heavy belting for high-load applications or a lightweight, open mesh solution, LinkCoo provides tailored options to optimize your operations.

LinkCoo offers a wide range of PTFE belts designed to meet the specific needs of various industries:

Standard PTFE Conveyor Belts

Antistatic PTFE Conveyor Belts

Open Mesh PTFE Conveyor Belts

Kevlar Reinforced PTFE Belting

Custom PTFE Conveyor Belts

1. Superior Heat Resistance:Withstands temperatures from -70°C to 260°C, ensuring reliable performance in curing processes, heat sealing, and screen printed material handling.

2. Non-Stick Surface:The PTFE-coated fabrics ensure a smooth, stick-resistant surface, preventing material buildup and enabling efficient operations.

3. Chemical Resistance:The PTFE conveyor belt resists harsh chemicals, solvents, and oils, making it ideal for demanding environments.

4. High Durability:Reinforced with coated fiberglass or PTFE coated fiberglass, the belts offer enhanced strength, crease tear resistance, and long service life.

5. Open Mesh Design:Available in open area configurations to allow airflow, making them suitable for curing processes and cooling applications.

6. Flexible and Customizable:From overlap splices to custom widths, LinkCoo’s PTFE heavy belting solutions can be tailored for any application.

7. Global Compliance:Certified by FDA, RoHS, and REACH, ensuring suitability for food production and other regulated industries.

1. High-Performance Materials

PTFE conveyor belts combine PTFE-coated fabrics with reinforced cores, delivering exceptional heat resistance, durability, and reliability for even the most demanding processes.

2. Customizable Solutions

With a wide range of open mesh, solid surface, and PTFE heavy belting options, LinkCoo provides tailor-made solutions to meet the specific needs of industries like food production, curing processes, and chemical processing.

3. Certified Quality

Every PTFE belt is manufactured to meet stringent industry standards, including FDA, RoHS, and REACH, ensuring compliance for applications that require food-grade or environmentally regulated materials.

4. Proven Efficiency Gains

From reducing downtime in heat sealing applications to improving airflow in curing processes, our PTFE conveyor belts are trusted by businesses worldwide to enhance efficiency and lower operational costs.

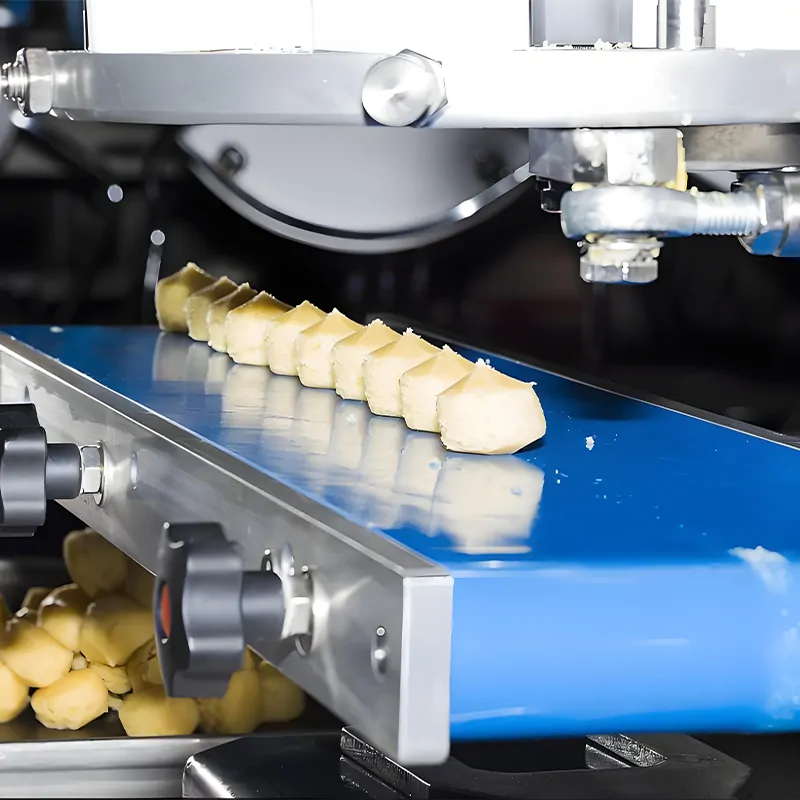

1. Food Production

2. Textile Manufacturing

3. Electronics Assembly

4. Chemical Processing

5. Industrial Printing

Food Production Facility

Electronics Manufacturer

Textile Production

From PTFE-coated fabrics and tapes to high-performance films and conveyor belts, we offer customized solutions to meet the unique demands of your business.

Backed by industry-leading expertise and trusted by businesses worldwide, we are committed to delivering durable, reliable, and efficient PTFE solutions that drive long-term value for your operations.

Contact us today to discuss your PTFE product needs and discover why we’re the partner of choice for industry leaders!

Since 2002, we have been committed to the research, development, production and manufacturing of PTFE coating products.

@ 2019 Likedoer All right reserved.