Home » PTFE Coated Kevlar Mesh

PTFE Coated Kevlar Mesh

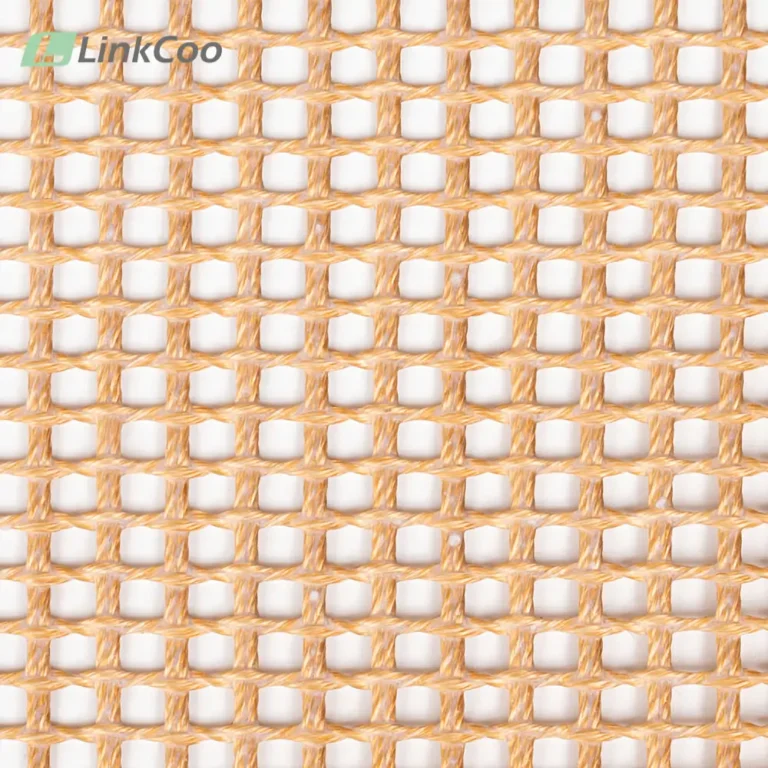

PTFE Coated Kevlar Mesh is engineered to combine the exceptional tensile strength of Kevlar with the high-performance properties of PTFE. This material offers extreme strength, high loading, and chemical resistance, making it ideal for application where extreme strength and durability are required. With an operational temperature range of -73°C to 260°C (-100°F to 500°F), it is highly temperature resistant and suitable for demanding industries. The open mesh structure ensures efficient airflow and heat transfer, while its light weight construction reduces operational energy costs. FDA and SGS certified, PTFE Coated Kevlar Mesh provides a long wear life in duty application where extreme performance is essential, such as industrial filtration, conveyor belts, and drying systems.

PTFE Coated Kevlar Mesh represents a breakthrough in industrial materials, offering unmatched performance in high loading and long wear applications. Constructed from kevlar fabrics with a durable PTFE coating, this mesh fabric provides superior resistance to wear, abrasion, and chemical exposure. The Kevlar base delivers higher tensile strength compared to traditional materials, while the PTFE coated open surface ensures non-stick properties and enhanced thermal stability.

This material is ideal for industries requiring temperature resistant solutions for mesh conveyor belting, coated kevlar mesh systems, and other high-stress applications. Its light weight design ensures energy efficiency in conveyor systems and filtration units, making it a cost-effective alternative to ptfe coated fiberglass or stainless steel.

The open mesh design optimizes airflow and heat transfer, which is particularly beneficial in drying and curing processes. Its ability to handle high loading and long wear makes it the preferred choice for duty application where extreme strength is required, such as in the automotive, food processing, and chemical industries.

PTFE Coated Kevlar Mesh offers a superior solution for industries requiring extreme strength, high loading, and durability in demanding environments. Its open mesh fabric design ensures optimal airflow and heat transfer, while its long wear life and lightweight construction reduce operational costs and energy consumption. Backed by FDA and SGS certifications, PTFE Coated Kevlar Mesh meets global safety standards and delivers reliable performance across a wide range of applications. Contact LinkCoo today to optimize your industrial processes with this advanced material.

Extreme Tensile Strength

- The Kevlar base offers higher tensile strength, allowing the mesh to handle high loading conditions without compromising durability.

Temperature Resistance

- Withstands temperatures from -73°C to 260°C (-100°F to 500°F), making it highly temperature resistant and ideal for high temperature environments.

Chemical and Abrasion Resistance

- The PTFE coated fabrics resist strong acids, alkalis, and solvents, ensuring long-lasting performance in chemically aggressive environments.

Non-Stick Surface

- The PTFE coated open structure prevents material adhesion, reducing cleaning downtime and improving system efficiency.

Open Mesh Design

- Facilitates airflow and heat transfer, optimizing performance in drying, curing, and filtration systems.

Lightweight Construction

- The light weight material reduces energy consumption in mesh conveyor belting, making it an energy-efficient solution.

Long Wear Life

- Designed for high loading and long wear, ensuring a long wear life and reducing replacement frequency.

Certified for Safety

- FDA and SGS certifications confirm its compliance with global safety and quality standards.

| Attribute | Specification |

| Material Composition | Kevlar Base + PTFE Coating |

| Operating Temperature | -73°C to 260°C (-100°F to 500°F) |

| Tensile Strength | ≥ 400 MPa (High tensile strength provided by Kevlar fibers) |

| Chemical Resistance | Resistant to strong acids, alkalis, organic solvents, and corrosive chemicals |

| Thickness Range | 0.25 mm to 1.5 mm |

| Weight | 0.45 kg/m² to 1.2 kg/m² (depending on mesh density and thickness) |

| Mesh Structure | Open mesh (2 mm x 2 mm or 4 mm x 4 mm available) |

| Air Permeability | 300 to 900 L/m²/s (depending on mesh size) |

| Abrasion Resistance | ≥ 5000 cycles (tested under ASTM D3884, Taber Abrasion Test) |

| Color Options | Black, Brown, Gray (custom colors available) |

| Certifications | FDA (food-grade certification), SGS (global safety certification) |

| Typical Lifespan | ≥ 2 years (under normal industrial operating conditions) |

| Model | Thickness (mm) | Mesh Size (mm x mm) | Weight (kg/m²) | Max Width (mm) | Recommended Applications |

| LKM-2501 | 0.25 | 2 x 2 | 0.45 | 1000 | High-temperature drying, lightweight conveyors |

| LKM-3502 | 0.35 | 2 x 2 | 0.6 | 1200 | Food-grade conveyor belts, chemical filtration |

| LKM-5004 | 0.5 | 4 x 4 | 0.75 | 1500 | Industrial filtration, chemical-resistant systems |

| LKM-7004 | 0.7 | 4 x 4 | 0.95 | 1800 | Heavy-duty conveyor belts, mining equipment |

| LKM-10004 | 1 | 4 x 4 | 1.1 | 2000 | High-load transport, aerospace manufacturing |

| LKM-15004 | 1.5 | 4 x 4 | 1.2 | 2200 | Specialized abrasion resistance, construction material transport |

1. Conveyor Belt Systems

- Industry: Automotive, food processing, packaging.

- Function: The PTFE Coated Kevlar Mesh is ideal for mesh conveyor belting in high-stress environments.

- Advantage: Provides a long wear life, reduces maintenance downtime, and ensures smooth material handling under high loading.

2. Industrial Filtration

- Industry: Chemical processing, pharmaceuticals, environmental protection.

- Function: Acts as a durable and chemically resistant filtration medium in systems handling corrosive materials.

- Advantage: Increases filtration efficiency and reduces operational costs over time.

3. High-Temperature Drying Systems

- Industry: Textiles, food processing, printing.

- Function: The open mesh design ensures uniform heat distribution in high temperature drying environments.

- Advantage: Reduces drying time, improves product quality, and minimizes energy consumption.

4. UV Curing Applications

- Industry: Electronics, coatings, printing.

- Function: The PTFE coated open surface ensures consistent curing performance, even under elevated temperatures.

- Advantage: Improves product consistency and reduces material defects.

5. Heavy-Duty Applications

- Industry: Mining, aerospace, construction.

- Function: The coated Kevlar mesh withstands abrasive and high-stress conditions, making it ideal for duty application where extreme strength is required.

- Advantage: Extends system lifespan and minimizes replacement frequency.

Client: Tesla (Conveyor Belt Systems)

- Challenge: High-stress conveyor belts experienced frequent failures under high loading conditions.

- Solution: Tesla implemented PTFE Coated Kevlar Mesh in its conveyor systems.

- Result: Extended belt lifespan by 300%, reduced maintenance frequency, and improved production efficiency.

Client: BASF (Industrial Filtration)

- Challenge: Chemical corrosion and material degradation caused frequent filter replacements.

- Solution: BASF adopted PTFE Coated Kevlar Mesh as a filtration medium.

- Result: Improved chemical resistance, reduced operational costs, and extended filter lifespan by 50%.

Client: Levi’s (Textile Drying Systems)

- Challenge: Drying systems faced uneven heat distribution and product defects.

- Solution: Levi’s replaced traditional materials with PTFE Coated Kevlar Mesh.

- Result: Reduced drying time by 30%, improved fabric quality, and lowered energy consumption by 20%.