Home » Anti-Static PTFE Glass Fabric

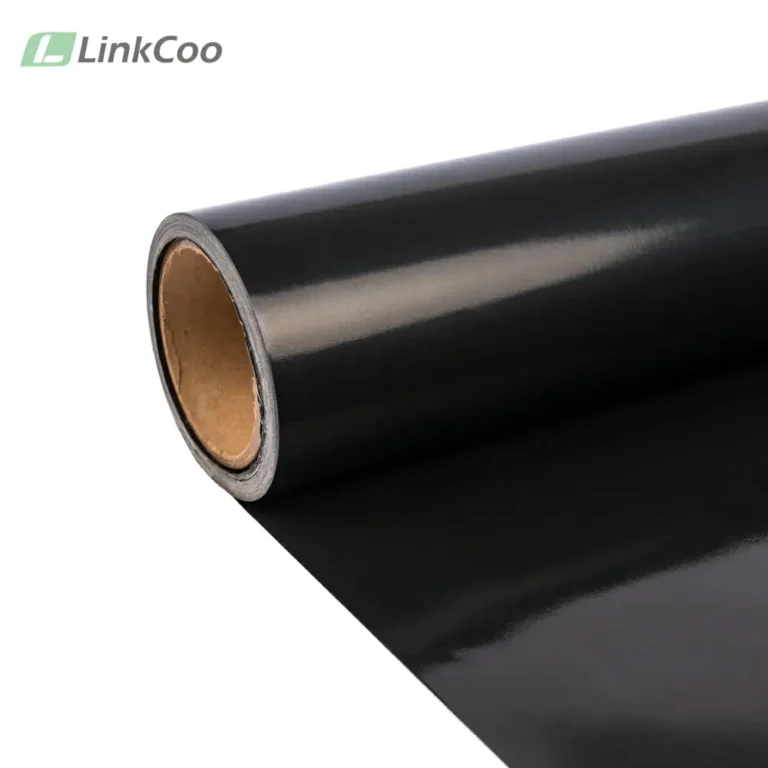

Anti-Static

PTFE Glass Fabric

Designed for static-sensitive environments, LinkCoo’s anti-static PTFE fabric combines exceptional static dissipation, heat resistance up to 260°C (500°F), and chemical stability. FDA and SGS-certified, this high-performance fabric is ideal for conveyor systems, electronics manufacturing, and chemical processing applications.

The anti-static PTFE fabric is purpose-built to address the challenges of electrostatic discharge (ESD) in industrial operations. Incorporating conductive additives such as carbon or graphite into the PTFE coating, this fabric ensures reliable static dissipation, making it indispensable in industries where static buildup can damage sensitive components, disrupt processes, or pose safety hazards.

Advanced Engineering for Anti-Static Performance:

LinkCoo’s anti-static PTFE glass fabric is manufactured using a proprietary coating process that achieves:

- Superior Conductivity: Surface resistivity as low as 10⁵Ω ensures rapid dissipation of static electricity, complying with ANSI/ESD S20.20 and IEC 61340 standards.

- Precision Coating: Uniform conductive PTFE layer enhances both static dissipation and mechanical durability.

- Reinforced Fiberglass Substrate: Provides high tensile strength and dimensional stability under stress, ensuring long-term reliability.

Core Benefits:

- Electrostatic Control: Effectively dissipates static electricity to prevent ESD-related damage or failures in sensitive environments.

- Thermal Resistance: Performs reliably across a wide temperature range (-73°C to 260°C), suitable for high-heat applications.

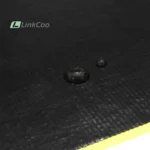

- Non-Stick Surface: PTFE coating offers excellent release properties, minimizing residue buildup.

- Chemical Stability: Fully resistant to corrosive agents, including acids, alkalis, and solvents.

- Durability: Designed for continuous use in high-stress operations, reducing maintenance and replacement costs.

Compared to standard PTFE-coated fabrics, the anti-static variant offers enhanced safety, operational reliability, and compatibility with static-prone environments.

LinkCoo’s anti-static PTFE fabric is the ideal solution for industries requiring static control, thermal stability, and chemical resistance. Engineered for performance, this fabric ensures operational reliability in applications ranging from electronics manufacturing to chemical processing and high-speed logistics. With FDA and SGS certifications, it meets the highest industry standards for safety and quality.

Contact LinkCoo today to learn how our anti-static PTFE solutions can enhance your operations.

- Anti-Static Technology: Dissipates static electricity efficiently, preventing ESD damage to components or interference with processes.

- Heat Resistance: Stable in extreme temperatures, up to 260°C (500°F), suitable for demanding industrial environments.

- Chemical Resistance: Chemically inert material ensures compatibility with harsh chemical exposure.

- Non-Stick Properties: Smooth surface prevents material adhesion, reducing downtime caused by cleaning.

- Longevity and Strength: Reinforced fiberglass fabric base ensures durability and dimensional stability under continuous use.

- Certifications: FDA and SGS certified, meeting global safety and industrial standards.

| Model | Color | Thickness | Width | Weight | Tensile Strength | Temperature Resistance |

| TG1Z8BK | Black | 0.08mm | 1250mm | 170 g/m2 | 130/120N/cm | -140 ~ 360C |

| TG1Y3BK | Black | 0.13mm | 1250mm | 275 g/m2 | 220/190N/cm | -140 ~ 360°C |

| TG1Y8BK | Black | 0.18mm | 1250mm | 415 g/m2 | 330/250N/cm | -140 ~ 360°C |

| TG1N5BK | Black | 0.25mm | 3200mm | 510 g/m2 | 410/330N/cm | -140 ~ 360C |

| TG1M5BK | Black | 0.35mm | 3200mm | 680 g/m2 | 560/445N/cm | -140 ~ 360°C |

| TG1A0BK | Black | 0.40mm | 4000mm | 820 g/m2 | 820/500N/cm | -140 ~ 360°C |

1. Electronics Manufacturing

- Industry: Semiconductor production, PCB assembly, and electronics packaging.

- Function: Reduces static buildup on conveyor systems, preventing ESD damage to sensitive components.

- Advantage: Ensures consistent product quality and minimizes production defects caused by static discharge.

2. Conveyor Systems in Packaging

- Industry: Food processing, logistics, and material handling.

- Function: Provides an anti-static, non-stick surface for smooth material transfer in static-prone environments.

- Advantage: Enhances safety and prevents operational interruptions due to static accumulation.

3. Chemical Processing Equipment

- Industry: Pharmaceutical and chemical manufacturing.

- Function: Mitigates static risks in volatile or flammable chemical environments.

- Advantage: Improves safety and ensures compliance with industrial safety regulations.

4. Industrial Laminations

- Industry: Textiles and composite manufacturing.

- Function: Maintains anti-static properties during lamination, reducing defects caused by static interference.

- Advantage: Enhances product consistency and quality in high-precision applications.

Client: Intel (Electronics Manufacturing)

- Challenge: Static buildup on conveyor systems during PCB assembly caused frequent ESD damage, reducing yield rates.

- Solution: Intel integrated LinkCoo’s anti-static PTFE fabric into its production lines, replacing standard conveyor materials.

- Result: Reduced ESD-related failures by 70%, improving overall production yield by 20%.

Client: BASF (Chemical Processing)

- Challenge: Static buildup in chemical reactors handling volatile substances posed a significant safety hazard.

- Solution: BASF installed LinkCoo’s anti-static PTFE glass fabric as protective linings in their reactors and storage systems.

- Result: Eliminated static-related incidents, achieving full regulatory compliance and enhancing safety standards.

Client: Amazon (Logistics and Material Handling)

- Challenge: Conveyor belts in high-speed logistics operations generated static, causing material adhesion and process disruptions.

- Solution: Amazon adopted LinkCoo’s anti-static PTFE fabric for their conveyor systems.

- Result: Improved material transfer efficiency by 30% and reduced downtime by 25%, saving $500,000 annually.